Associations Want to Keep Lifelines Open with Freight Rail!

Mar 26, 2020 at 6:03 PMBdKEP Establishes a Corona Situation Center for Its Members

Mar 26, 2020 at 6:42 PMThe Federal Association of Logistics (BVL) assists its members during crisis times and provides tips on logistics services for goods flows in times of Corona, with the involvement of industry experts. All modes of transport and contract logistics are examined. A useful aid in these unpredictable times.

(Bremen, 26.03.2020) Occasionally, one finds thank-you messages on social media – to all truck drivers, postal and parcel deliverers, employees in grocery stores, pharmacies, transport companies, and other sectors that have been classified by politics and society as “essential” and thus system-relevant. This is motivating for those working in logistics. Indeed, the supply and distribution of essential goods in our country is functioning well. Logistics professionals in industry and trade, as well as logistics service providers, make valuable contributions to the functioning of our society and the supply of the population – even in crisis times.

Even in “normal” times, the tasks are not trivial and require expertise and perfect organization. In crisis times, additional obstacles and cost drivers arise that can only be mastered in close cooperation between politics, business, and society. Overall logistics and contract logistics should therefore be regarded as system-relevant services and receive corresponding relief and support.

In the area of goods volumes, (cargo space) capacities, and logistical infrastructure, there are currently several challenges:

1. Missing Volumes in European Land Transport

Production has decreased significantly, and consequently, transportation has also decreased significantly. The general cargo business in European land transport is driven by fixed costs. The main routes between regional transshipment points (each network in Germany comprises about 40 of these) and European destinations must continue to be maintained; otherwise, transit times would be severely extended. The fixed cost share per shipment is thus increasing, and general cargo is becoming more expensive, not only in Europe but also nationally in Germany. After the crisis, a new equilibrium will form.

2. Fewer Goods Flows in Specialized Networks

In addition to general cargo networks, there are specialized networks, for example, for sensitive goods, pharmaceuticals, and IT devices. To protect against Corona viruses, most administrations have closed their entrances to external personnel. The buyer who knows this does not place orders. Other buyers who continue to order cause deliveries that take significantly more time due to problems in delivery. Therefore, for specialized networks: less volume, yet a fixed number of main routes and more problematic deliveries, thus making logistics services more expensive.

3. Parcel Services

Parcel service providers transport, among other things, life-saving medications, food, and urgently needed spare parts, whose reliable nationwide and Europe-wide delivery is essential for the entire economy, especially in a crisis situation. The importance of parcel services and a functioning infrastructure goes far beyond the supply of consumer goods and concerns basic material supply needs.

All parcel service providers jointly ensure universal parcel supply. In Germany, a differentiated market of parcel service providers has developed, which derives its performance from the competition among companies. Therefore, unilateral support for only certain companies must be excluded if the supply of the population is to be ensured.

4. Rail

The rail is also crucial for ensuring logistical processes and keeping the systems running. Currently, rail transport is functioning largely without disruptions across borders. The acute, situational shortage of truck drivers in Europe, problems for trucks at borders, and the high safety of rail transport are driving demand for capacities in combined transport.

Without knowing how demand will develop in the coming weeks and months, new, diverse challenges are being mastered with emergency plans. This includes, for example, ensuring accommodations for train drivers during times when hotels are closed, as well as trips to deployment locations with reduced schedules in passenger transport.

However, even on the rail, traffic is declining, as is currently the case due to the Europe-wide factory closures in the automotive industry and further extensive production stops this week in Italy. Over 50% of rail freight transport services in Germany are provided by a multitude of medium-sized companies. With low margins, companies in rail transport rely on very high utilization of the systems, as extensive infrastructure and facilities must be maintained. Not only is the basis for urgently needed investments, e.g., for the digitization of the rail system, threatened, but the situation can also become existentially dangerous for many companies. Reducing infrastructure usage fees, e.g., costs for tracks and necessary parking of locomotives/carriage fleets, as well as the elimination of the EEG levy would lead to a noticeable relief for companies.

Particular attention must be paid to the functionality of terminals in Europe. Here, in collaboration with the industry and in coordination with other European infrastructure operators, it must be decided which locations are system-relevant.

5. Missing Reusable Containers

In overseas transport, containers are missing in the economic cycle. The Corona crisis began with the turn of the year 2020 in China – the Asians are thus three months “ahead” of Europe. In these three months, goods were sent in containers from Europe and the USA to China. However, China produced much less, resulting in 6 million TEU of empty container capacity now lying in China. These are missing here in Europe or in the western trading area. Restoring parity will cost billions.

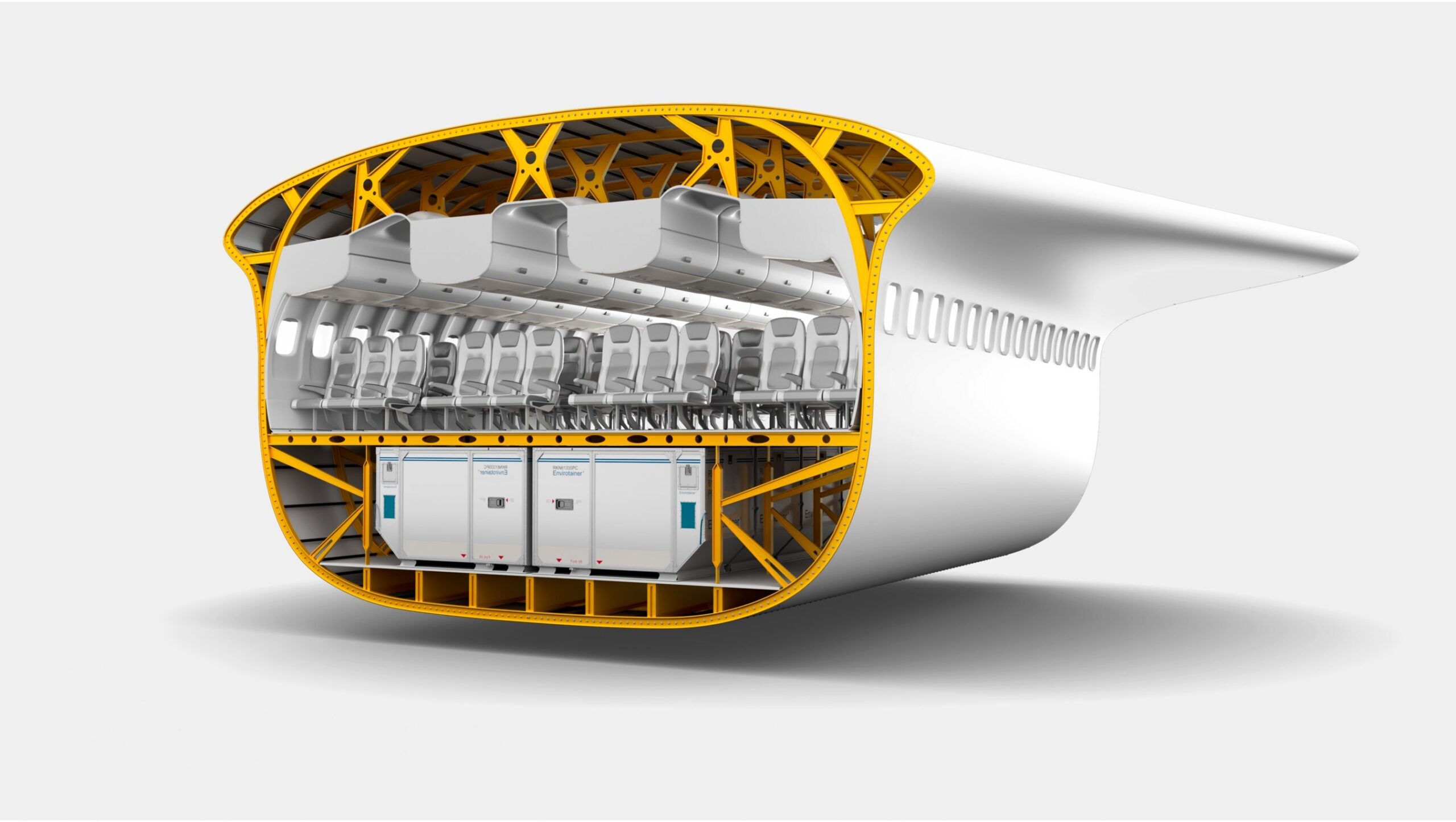

6. Missing Air Freight Capacity

Air freight is indispensable for transporting high-quality and time-sensitive goods in overseas trade. On these trade routes, half of the world’s air freight is transported as belly-freight (cargo in passenger planes). This creates synergies between passenger and cargo. Since many passenger flights are currently being canceled, this capacity is now lacking. Separate transport aircraft must be deployed. To compensate for the missing belly cargo capacities, passenger planes can also be used for pure freight transport if necessary – at then higher costs for the freight airline. Airlines are already working on corresponding models.

In addition, individual countries can currently only be connected without a crew layover, which requires a larger crew deployment for these flights. Consequently, air freight is becoming significantly more expensive.

Air freight also requires local networking with the European area via land transport and is thus directly affected by restrictions (e.g., additional border controls, staff shortages, company liquidity) in land transport.

7. Port Economy

Terminals and facilities in the port must always be accessible and functional, as they are system-relevant. This applies even with lower volumes and in light of all legal regulations and their consequences, such as additional necessary childcare. In the coming weeks, rather half-empty to empty ships are expected in the port, with fewer containers and fewer vehicles arriving. This causes imbalances in the “equipment flow” and thus additional costs, which are described in more detail in section 5 “Missing Reusable Containers.”

In automotive transshipment, the closure of automotive plants will soon be noticeable. Additionally, free capacities are emerging in the intermodal sector, known as “standing capacities.” Small and medium-sized enterprises, especially self-driving companies, are suffering from this.

8. Contract Logistics

Contract logistics is also facing significant challenges. While online retail is experiencing high volume increases, other customers are completely halting production. For the executing contract logistics service providers, this means increased utilization at some locations and drastic declines at others. The pharmaceutical logistics is also extremely demanding. Here, logistics service providers are trying to ensure that drivers can actually deliver life-saving medical products, etc. For this purpose, for example, letters are provided that inform the controlling authorities about the cargo and relevance of the shipment. Pharmacies are stocking up, including with vaccines and medications that are not related to the Corona virus, such as vaccines against measles or mumps.

Like the producing companies, contract logistics providers are often organized cross-border. It is a hindrance and creates increased organizational effort that federal states and European countries have different definitions of crisis areas and the corresponding measures.

Example: In the Czech Republic, wearing face masks is now mandatory. Here, logistics service providers must react quickly and pragmatically. The company Loxxess, for example, has employees sewing masks at home.

9. Staff Shortages Due to Corona Precautions

Many employees in contract logistics and warehouse logistics have their primary residence in neighboring countries to the east of Germany. Because the borders are now closed, and these employees fear contracting the virus in communal accommodations or simply due to the generally uncertain situation, many of them are staying at home. Logistics service providers must deliver their performance in warehouses and goods handling centers, sometimes even coping with a drastically increased demand for consumer goods – and then with untrained or inexperienced employees. Many sick reports from neighboring countries require extensive administrative follow-up. Efficiency decreases in both operational and administrative areas, personnel costs rise, and thus performance becomes more expensive.

10. Additional Costs Due to Childcare

To reduce infection risks, federal and state governments have decided not to allow children and adolescents to attend kindergartens and schools. These decisions are important and correct. The Federal Minister of Labor has urged the economy to interpret §616 BGB very generously.

For employees in administrations and offices who work from home, this is relatively easy, but not for those who, as logistics workers, drive forklifts or load trucks. For employees in the automotive industry who are at home on short-time work or forced leave, childcare is also manageable.

Furthermore, politics has recognized that there are economic and social sectors that are particularly important and critical for the common good, such as fire departments, police, medical personnel, and specific authorities. In these areas, care for children in schools and daycare centers has been ensured. In NRW, this was regulated by decree on March 13, 2020.

However, employees from logistics do not benefit from “emergency care” in schools and daycare centers. Replacement workers must be provided, which reduces the efficiency of processes. Logistics in industry, trade, and services becomes more expensive as a result.

11. Small and Medium-Sized Enterprises in the Transport Industry

Many small and medium-sized transport companies have never negotiated a loan with a bank. Trucks are usually leased. The rest is paid with what is in the account. These people are often entrepreneurs with a migration background. They are often overwhelmed by the formalities and bureaucracy associated with applying for liquidity-secure funds from KfW. Applications must now be simplified and processed quickly and easily.

From the Food Trade

There is also a shortage of employees from Eastern Europe in the food trade. It is advisable to work with logistics service providers who are currently underutilized in other sectors. In addition, one can deploy one’s own employees from less utilized areas such as gastronomy and large consumers, who are currently less busy. Efficiency still decreases. It is also extremely important to deal solution-oriented with regulations on personnel leasing.

Childcare is clarified for food logistics, as this area is part of critical infrastructure. The clarification was pragmatically conducted through phone calls with district administrators or state governments. Emergency certificates are issued and accepted.

The retail sector now sees not only the state as responsible, which is already extremely burdened in healthcare: entrepreneurs must report their current risks, but they should also independently initiate pragmatic and courageous measures to mitigate damage – such as selling off currently unnecessary stock or quickly reallocating personnel.

General Priority Topics

In a conference call between decision-makers from large logistics service companies, association representatives, and the Federal Ministry of Transport, several topics were identified as priorities:

- Securing post and parcel stations: keeping corresponding businesses open

- Borders should remain open for freight transport; border controls hinder freight transport as a side effect

- Proof documentation of the travel purpose for cross-border freight transport

- Flexible deployment of labor

- Securing liquidity, for example, through short-time work

Conclusion:

The logistics sector is happy to do its job and is proud that even under crisis conditions, it succeeds in ensuring the functioning of the German economy and the supply of the population. However, the services provided must be compensated in such a way that the costs incurred can be covered. Logistics must be economically viable! If additional costs arise from government decisions, it must be clear who bears this burden.

There are numerous ways to create financial relief for the economic sector and positively influence the liquidity of companies in logistics and supply chain management. These include deferrals of social security contributions or tax deferrals, for example, on import sales tax. This happens in other countries only after six months; here, however, immediately, and this means unequal treatment for the logistics location Germany.

A federal contribution to childcare must already be established in the Infection Protection Act to prevent people from having to stay at home because daycare centers are closed.

With contributions from Berit Börke (TX Logistik), Frank Dreeke (BLG Logistics Group), Peter Gerber (Lufthansa Cargo), Karl Gernandt (Kühne + Nagel), Christian Grotemeier (BVL.digital), Klemens Rethmann (Rhenus), Frank Sportolari (UPS), Christina Thurner (Loxxess), Thomas Wimmer (Federal Association of Logistics), and Stephan Wohler (EDEKA Minden-Hannover)

Photo: Pixabay

www.bvl.de