Moving Packages and Changing Times for the Austrian Post

Dec 2, 2025 at 6:06 PM

Reckitt Becomes Anchor Tenant in Garbe Park Klášterec nad Ohří II

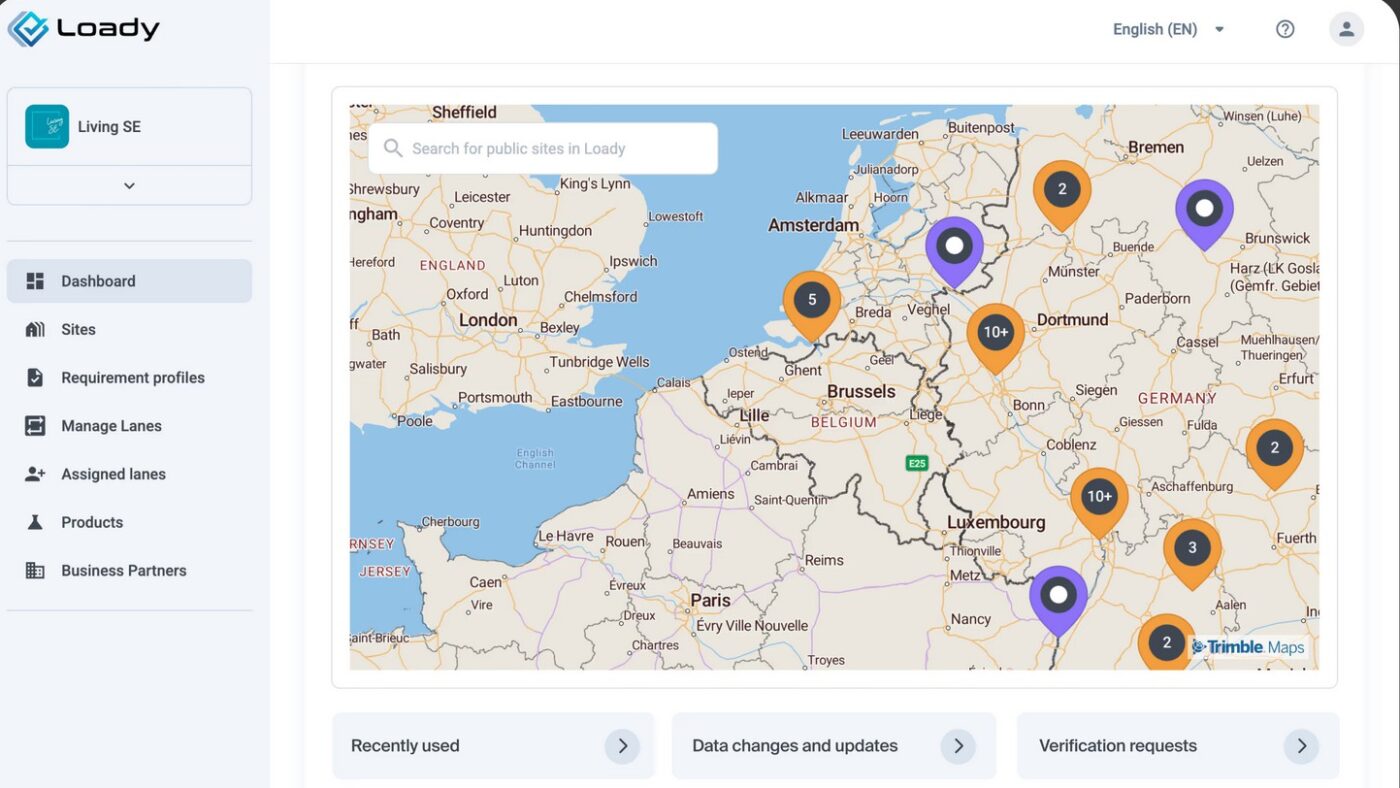

Dec 4, 2025 at 1:16 PMLoady GmbH has published a white paper on the digitization of pre-loading restrictions in liquid logistics. The position paper analyzes the current situation with fragmented data and demonstrates how structured pre-loading restriction data can improve inspection processes in the chemical, feed, and food industries, and how efficiency and sustainability gains can be achieved.

(Mannheim) Loady structures pre-loading restrictions in a chemically and logistically consistent data model. Each substance is uniquely identified by CAS and EC numbers, synonyms, and multilingual designations. Rules can be defined at the substance or group level and provide clear statuses. Companies maintain their restrictions centrally in Loady and can import existing lists in a structured manner. The platform offers API interfaces for synchronization with ERP and QHSE systems as well as export functions. The use of structured pre-loading restriction data reduces manual inspection efforts by up to 80%, avoids rejections through valid scheduling, and lowers CO₂ emissions by reducing multiple trips and unnecessary cleanings.

The solution is deployed at three levels: dispatchers, loaders, and cleaning companies check whether product combinations are permissible and what cleaning procedures are required. Freight forwarders and loaders conduct structured Previous Load Restriction Checks (ePLR) by entering up to five previous loads and receiving validated results immediately. Pilot customers integrate the ePLR logic into transport and yard management systems for automatic checks before scheduling or gate release.

Integration of Electronic Cleaning Certificates

Loady is working on integrating the ePLR logic into electronic cleaning certificates such as the eECD from ECLIC or Bulkvision certificates. In the future, cleaning certificates could be automatically checked against valid pre-loading restrictions – the cleaning station transmits the previous product and cleaning code, Loady validates the information, and records the inspection result directly in the certificate.

“Structured pre-loading restriction data is a fundamental advancement for quality and safety in liquid bulk logistics,” explains Elzbieta Wiankowska, COO of Loady GmbH. “Loady is now an independent solution and at the same time a central building block of a digitally connected future.”

Download the white paper for free here

Photo: © Loady