Logivisor Reports Strong Increase in Vacant Logistics Spaces

Mar 19, 2024 at 8:44 PM

Online System Logistics with More Transparency in Local Transport

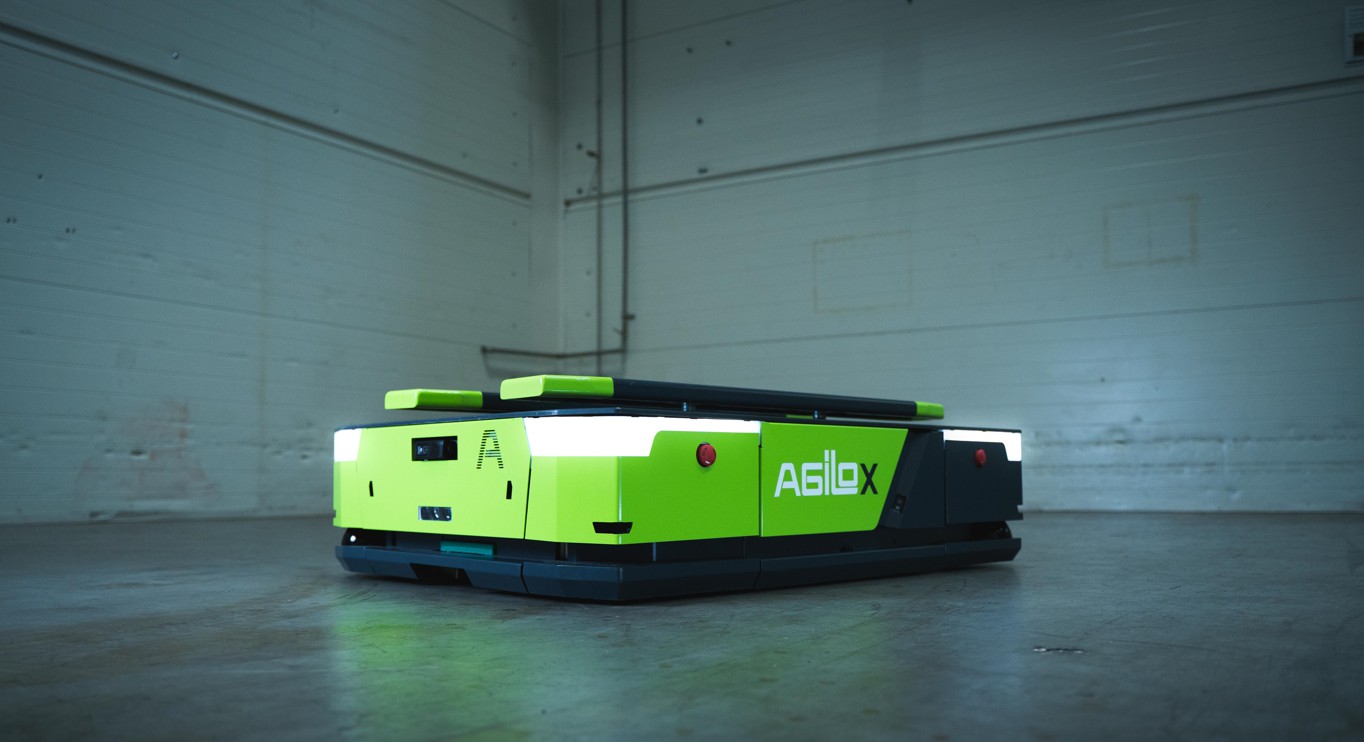

Mar 21, 2024 at 3:12 PMAGILOX Services GmbH, a technology company for Autonomous Mobile Robots (AMR), expands its product portfolio with a powerful and flexible undercarriage robot. Ideal for manufacturing and warehouse logistics, the AGILOX OPS can be put into operation within 12 hours, with additional AMRs of the swarm operational within a few hours.

(Neukirchen/Lambach) The AGILOX Omnidirectional Platform Shuttle (OPS) marks a significant milestone in AGILOX’s product portfolio. The Autonomous Mobile Robot (AMR) effortlessly transports loads of up to 1,500 kg. Four omnidirectional drive units and a slim design enable easy and safe navigation in narrow aisles and confined spaces. Thus, the AGILOX OPS is an optimal solution for existing facilities. Additionally, the AGILOX OPS offers maximum efficiency with a top speed of up to 1.9 m/s.

With flexible load handling devices and maximum navigation accuracy (+/- 4 mm), the AGILOX OPS allows for quick goods turnover and efficient transport from station to station. Its innovative platform design enables seamless integration into existing processes and provides maximum safety in a human-robot environment.

Swarm intelligence for maximum flexibility & user-friendliness

The AGILOX X-SWARM technology ensures seamless interaction of the AGILOX OPS with other AGILOX AMR models in a swarm. Fleets can be easily and quickly expanded with additional robots within a few hours. All AMRs in a swarm communicate directly and exchange information about their own position and current status multiple times per second. This allows them to intelligently distribute orders. Goods are automatically prepared, free paths are found, and they adapt effortlessly to changes in the environment. In the event of a robot failure, the remaining AMR swarm takes over responsibility and ensures a secure flow of goods. Under-supplies and transit times on transport routes are fully optimized automatically. Thanks to fast charging, each AMR is ready for use again in just a few minutes.

“At AGILOX, we have made it our mission to simplify and secure processes as much as possible through the use of high-tech robots. The new AGILOX OPS is another strategic building block in the AGILOX product portfolio to tap into new market segments,” says Jürgen Baumgartner, Chief Sales Officer at AGILOX.

Diverse selection of individual load carriers

The AGILOX OPS is also versatile and finds applications in numerous manufacturing and warehouse logistics scenarios. Particularly where conventional autonomous forklifts reach their limits due to limited space. Examples include the transport of industrial waste directly to the production line or the provision of materials at workstations. Additionally, the OPS offers the possibility to adapt load handling devices to individual load carriers, further expanding its range of applications. Its innovative platform design enables seamless integration into existing processes to transport individual load carriers on the part of customers.

Photo: © Agilox