Preventing Corrosion on Drums and IBC Frames During Transport

Jun 21, 2023 at 1:40 PM

The Cargo Trans Logistik (CTL) network now counts over 180 partners

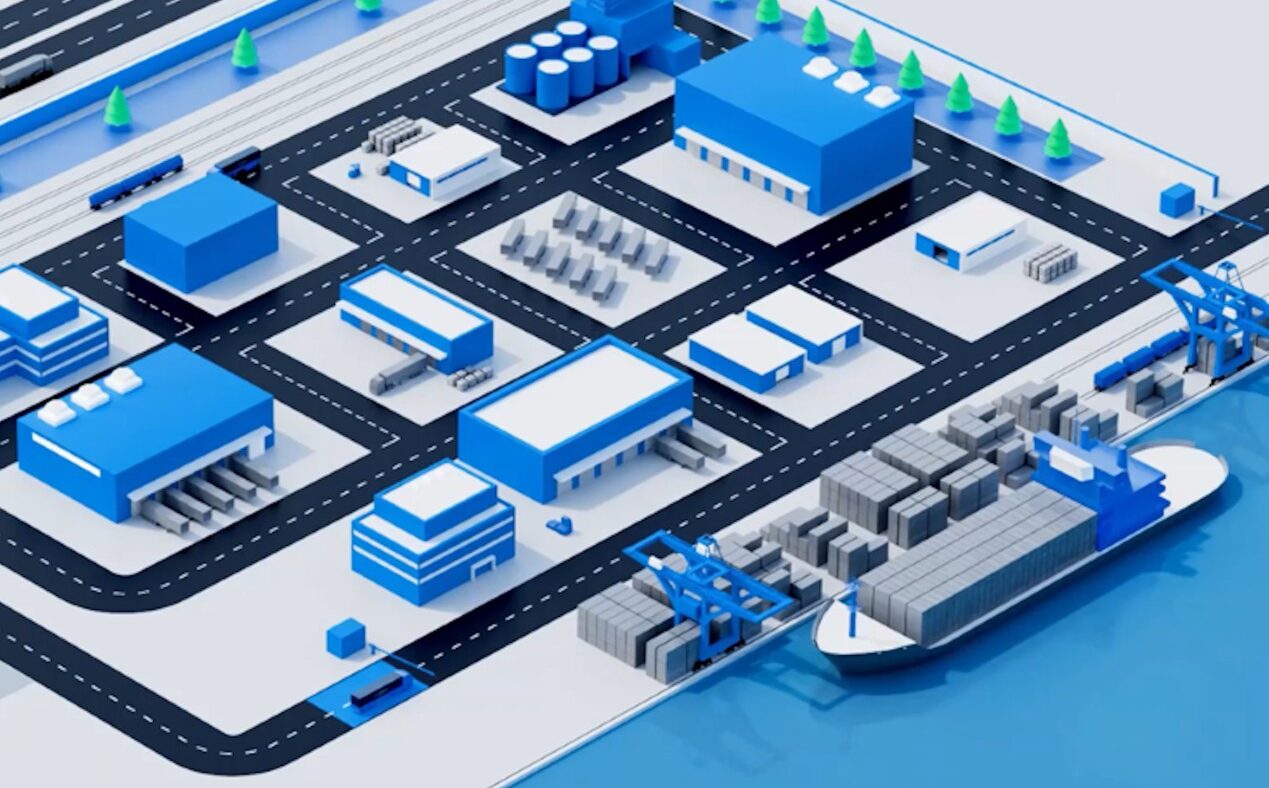

Jun 21, 2023 at 2:52 PMThe optimal yard management is the topic of the hour. For many companies, it is a challenge to maintain an overview and stay in control amidst highly dynamic and increasingly complex factory logistics and production processes. The yard, in connection with storage and transport processes, serves as the pivot point for the entire planning of supply chains – digital, global, and scalable – this is the focus of leogistics GmbH, a leading driver of the future of supply chain management.

(Hamburg) The logistics experts from Hamburg have now developed a new planning solution specifically for their customers and presented it for the first time at the LogiMAT trade fair in Stuttgart: “leoPlan” will specifically optimize the execution of transport orders on factory, industrial, and production sites of industrial companies, as well as related processes in trailer and swap body management. Integrated planning of complex logistical processes – this is the guiding principle of the new leogistics offering.

“Well planned is half the battle for efficient yard logistics. To act instead of improvising – that must be the goal of companies. We support them with state-of-the-art technology. leoPlan simplifies the planning of orders as well as complex order chains. The solution continuously reconciles the planned capacity needs with the available capacities. With leoPlan, plans and real-time data can be reconciled in real-time. Companies will no longer be able to do without this tool if they want to act proactively in the yard and efficiently process goods internally,” explains Christiaan Carstens, a member of the management board at leogistics.

Integrated Capacity Management

The new solution provides integrated capacity management that supports the deployment of the right drivers, the right tractors, the right forklifts, the right trailers in sufficient numbers, and the necessary resources at the requested time. Additionally, leoPlan includes the mapping of shift allocations (integration into HR/HCM systems), rolling planning adjustments based on real-time information, continuous identification of potential planning conflicts, and system-generated proposals for solutions. Furthermore, the solution offers automatic scheduling of transport/work orders, assignment of orders to the respective executing resources (transport vehicles, tractors, forklifts, etc.), digital processing of transport, work, and yard orders, real-time-based processing of planned orders, the use of mobile apps for work orders, and continuous monitoring of performance with planned/actual deviations and other configurable KPIs.

leoPlan is also an important step towards green logistics, meaning the optimal utilization of existing capacities and CO2 reduction. “The goal must be to transport more with the available capacities and to avoid unnecessary transports and empty trips. Our solution supports companies with new, revolutionary approaches,” explains Carstens.

Diverse Application Areas

The application areas of the solution are diverse. leoPlan can be used wherever goods are transported internally within production facilities, ports, terminals, etc., and where work orders or order chains are executed. The solution is ideal for chemical producers with so-called pre-loading concepts or for automotive plants, where a finished vehicle must be transported from the pickup point to the car loading area. In aircraft manufacturing, where it often involves transporting production parts to the manufacturing site, the solution is also used, as well as in large steelworks, where, for example, the disposal of production and the transport of steel strips and sheets to storage areas must be organized. Last but not least, leoPlan is interesting for retailers and their warehouses, where the goal is to ensure a highly scheduled and absolutely smooth nationwide or even Europe-wide supply to branches.

Photo: © leogistics