Mercedes eActros Truck Overcomes Arlberg Pass

Oct 20, 2022 at 12:43 PM

Ralf Heersma-Plattner appointed Managing Director at Grieshaber

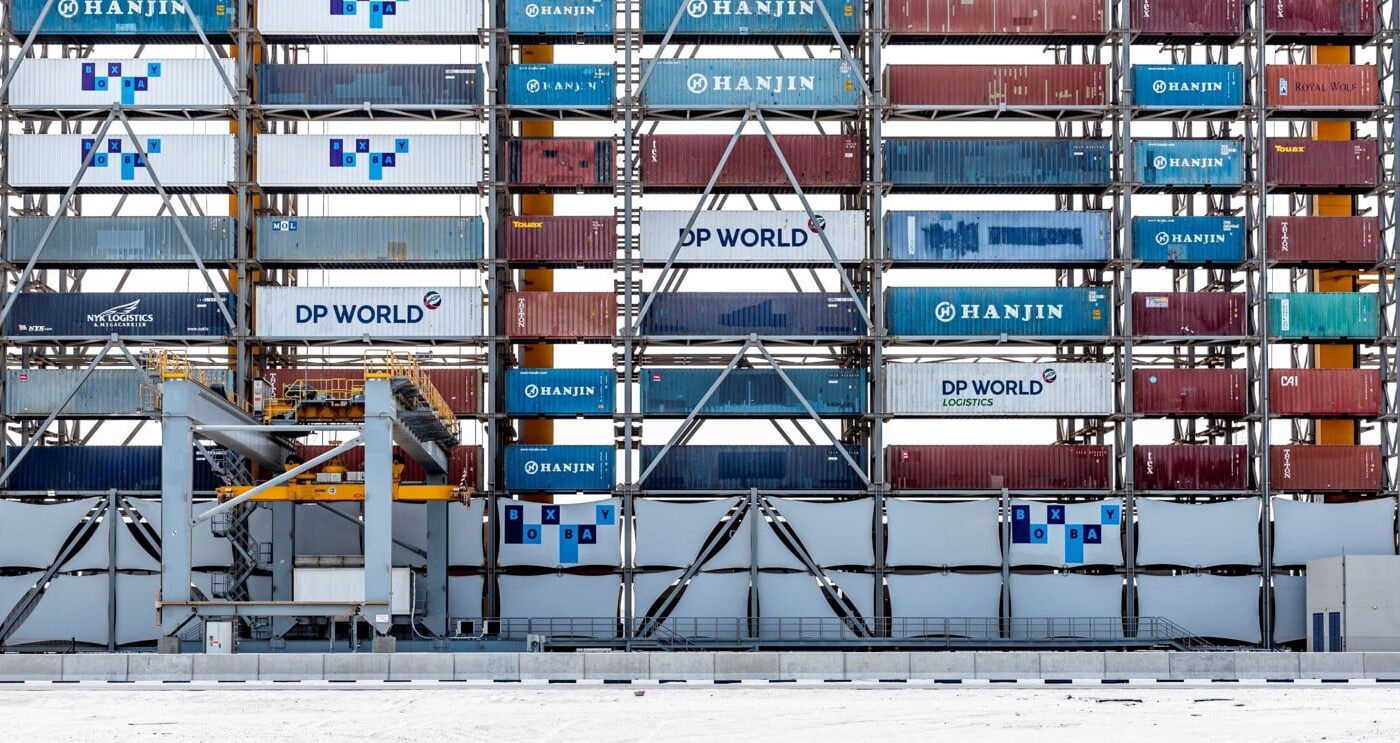

Oct 21, 2022 at 2:53 PMThe Boxbay concept from the plant manufacturer SMS wins the German Logistics Award 2022. 90% of global goods traffic occurs via sea routes. Ports worldwide are reaching their limits: space is insufficient to manage the growth of goods traffic, turnaround times are too high, as are noise and light emissions, and energy consumption in the terminals. Now there is a solution that addresses all these problems. Boxbay has already proven itself in a pilot project in Dubai.

(Bremen/Berlin) Triple the storage capacity of a container terminal on the same area and completely avoid the cumbersome and unproductive re-stacking. This solution comes at a time when, due to ever larger ships, more and more containers must be unloaded, temporarily stored, and reloaded during a port stop. At the same time, the average dwell time of a container at the terminals has continuously increased, also due to the well-known supply chain issues. To make supply chains more robust, terminals need greater buffer capacity, which is usually not achievable on limited spaces with conventional processes. “Looking back at the history of the container, nothing significant has changed since its introduction in 1956,” says Carsten Heide, head of project management at SMS subsidiary Amova. The Boxbay concept, functioning like a high-bay warehouse for containers of all standard sizes, now radically changes the processes at the terminals: instead of a maximum of six containers, up to eleven boxes can now be stacked on top of each other. Most importantly, these are stored separately and not directly on top of each other, allowing for the complete elimination of re-stacking. Containers can be loaded and unloaded from multiple sides of Boxbay. A surrounding transport system that connects the aisles creates flexibility and speed in handling.

Quay-side handling technology can continue to be utilized

Quay-side handling technology can continue to be utilized

In January 2021, as a proof of concept, the partner SMS Group and DP World commissioned the first facility in the port of Dubai. With a complete expansion of the 230-meter-long, 26-meter-wide, and 50-meter-high pilot facility, 500 inbound and outbound movements per hour can be realized on the water side and 300 inbound and outbound movements per hour on the land side. The quay-side handling technology with the existing container bridges can continue to be used as before. The boxes are then taken over by the transport systems deployed in the terminal and transported to the receiving position of the Boxbay warehouse. There, powerful stacker cranes take over the containers and transport them through aisles to the storage locations of Boxbay. Below the warehouse, there is a surrounding rail-bound pallet transport system that brings the containers to the land-side truck or rail transfer station or picks them up.

Emission-free with electric energy

In contrast to many conventional systems, Boxbay is operated completely emission-free with electric energy and can work CO2-free in conjunction with green electricity. The roof of the facility can optionally be equipped with a large-scale photovoltaic system that produces electricity for the operation of the facility or even generates an energy surplus. Vertical gardens on the exterior cladding can also purify the air and lower the surrounding temperature. By expanding capacity without additional space, further land development and significant interventions in nature and ecosystems can be avoided.

The Boxbay concept convinced the jury and clearly prevailed against the competitors in the end. Jury chair Dr. Ursula Weidenfeld emphasized in her laudation that the project meets not only the innovation criteria but also the newer criteria for the German Logistics Award, such as social relevance and improvement of resilience: “In the Boxbay project, it is most evident: we see a densification of container areas to one-third, noise and light protection, electricity generation beyond its own needs, the integration of existing port handling technologies, and the optional access to every container. Although Boxbay is still a test facility in Dubai, the entire facility complex already meets all the criteria and goals of the German Logistics Award,” said Weidenfeld.

Pleased (l. to r.): Prof. Dr.-Ing. Thomas Wimmer (BVL), Bernd Büdenbender (Amova), Christoph Roth (SMS group), Carsten Heide (SMS group), Ronald van der Meer (DP World) Volker Brück (SMS group), Bernd Klein (SMS group), Martin Aufschläger (SMS group), Dr. Mathias Dobner (SMS group), Dr. Ursula Weidenfeld (Jury chair), Christina Thurner (BVL) (Photo: © BVL)

Heureka and Volkswagen Group Components as additional finalists

Also in the finals of the German Logistics Award were two concepts from Volkswagen Group Components in Braunschweig and Heureka Business Solutions in Mannheim. At VW, it is about the production and logistics of battery systems for electric cars. Starting from transport by rail and electric trucks to the highly automated material flow system and automatic loading, an impressive and innovative overall concept is presented here. Heureka applied with a new concept for healthcare logistics at the Mannheim Clinic. The application presents the optimization of intralogistics using artificial intelligence and a digital twin against the backdrop of the special challenges of a large hospital operation.

Photos: © SMS Group