Why the Supply Chain Act Can Bring Business Advantages

Jun 16, 2022 at 7:45 PM

TGW Know-How Accelerates Home Electronics Specialist Jasco

Jun 20, 2022 at 5:40 PMThe Dortmund-based xpack green logistics GmbH & Co. KG is dedicated to reusable packaging in the field of parcel logistics and is taking on resource-consuming single-use packaging. With the TyrePack for wheels and tires, the young company can already refer to a practical success story.

(Dortmund) Packaging leaves behind gigantic mountains of waste, especially single-use packaging. In Germany, around 220 kg of packaging waste is generated per person each year. The xpack green logistics GmbH & Co. KG has taken on this unpleasant fact and aims to counteract it with reusable packaging. In addition to waste, packaging also generates CO2 emissions, whether during production or recycling. Furthermore, transport packaging typically contains a lot of “air,” which is additionally stuffed with filler material. This has increased even more due to e-commerce.

Founded in 2018 by Lothar Preis, Ralph Kesting, and Jan Opländer, the young company xpack is now contributing to reducing packaging waste with smart reusable packaging. Lothar Preis adds: “During my time as a manager at a leading parcel service provider, I already thought about how to reduce packaging waste. This is how the idea matured into a patent, and in 2018 we were able to implement it.”

The founders of xpack green logistics GmbH & Co. KG (from left to right): Ralph Kesting, Jan Opländer, and Lothar Preis

The founders of xpack green logistics GmbH & Co. KG (from left to right): Ralph Kesting, Jan Opländer, and Lothar Preis

It all started with the TyrePack

Right from the start, the company launched the TyrePack, a reusable packaging for wheels and tires. “Wheels and tires present special requirements for parcel shipping due to their weight and need for protection. There have also been accidents in parcel sorting facilities when shipping unwrapped tires. Therefore, we launched the TyrePack, a closable value-added packaging specifically designed for the requirements of parcel logistics.”

Since 2018, over 35,000 shipments have been sent with a TyrePack. More than 300 B2B and over 1,000 C2C customers are very satisfied. The return rate of the empty packs was a remarkable 96%, and the damage rate remained below 0.1%. At the same time, this number of shipments also saved 72,000 kg of CO2.

xpack adapts to the contents and offers various sizes

Tyrepacks and xpacks are produced in Europe, and there are four different sizes available. Custom solutions are also possible. The pack adapts to the contents, so no unnecessary “air” is transported. Due to its robustness, the xpack provides high protection for the contents of a shipment.

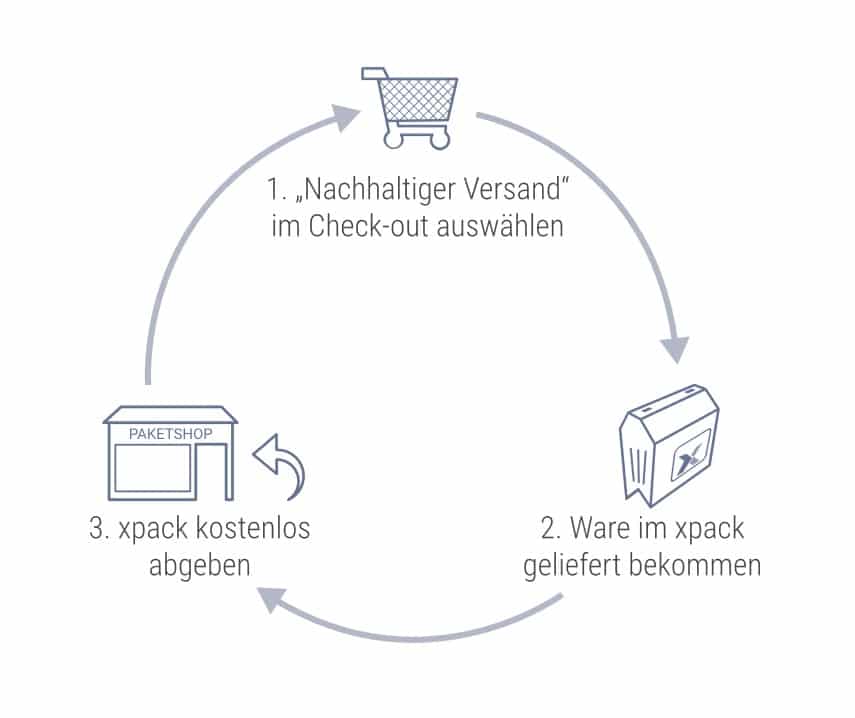

However, xpack sees itself not just as a supplier of packaging but offers the complete system. From incentive systems to IT support and returns management, the company provides the entire process for a circular reusable packaging model. The packaging and all services required for a functioning reusable model can be utilized through a performance-based pricing model (“Pay-Per-Use”). To increase the willingness to return, an incentive system has been created. Once an xpack has served its purpose after about 25 cycles, it is recyclable.

The challenge lies in the return of the packaging

For both the TyrePack and the xpack, the real challenge is returns management. Preis states: “We do not charge a deposit upfront. That would deter many buyers. The recipient is given a two-week deadline for the return of the empty packaging. Through our sophisticated IT platform with interfaces to parcel services, we know exactly where the packs are and can automatically inform recipients about return questions and, if necessary, remind them. Only when a pack truly does not come back do we charge a protection fee. In 2C shipping, the recipient can consciously choose a reusable packaging as an alternative to single-use packaging at the time of ordering. This does mean a slight adjustment to the sender’s IT, but it helps all parties in their efforts for more sustainability and is therefore gladly chosen.” Through interfaces to parcel services, the recipient can already see in the shipping information that it is a returnable reusable packaging.

Understanding of a circular economy, even in packaging, is growing, as is the sensitivity to the fact that packaging should not be destroyed but returned.

From start-up to medium-sized enterprise

In its current phase, xpack is evolving from a start-up to a medium-sized enterprise. “We achieve good cost coverage. We expect to break even in three years.” The young company currently employs 10 people. “They represent a cross-section of our society. Young and old, women and men, work hand in hand. We also work decentrally, offering interesting and modern workplaces,” Preis is convinced.

About xpack green logistics GmbH & Co. KG

xpack is more than just a reusable packaging: xpack is a system provider for circular packaging and helps its customers minimize their CO2 footprint and waste. Furthermore, the company enables IoT for your logistics chain and supports this process with its own IT services. All xpack can be equipped with individual sensors and adapted to your needs.

xpack won the “Eco Performance Award 2022” in the category “Transformer of the year.” Lothar Preis (left, CEO) and Simon Hinz (Development, IT) present the trophies (© Loginfo24)

xpack won the “Eco Performance Award 2022” in the category “Transformer of the year.” Lothar Preis (left, CEO) and Simon Hinz (Development, IT) present the trophies (© Loginfo24)

xpack won the “Eco Performance Award 2022” in the category “Transformer of the year.” Lothar Preis (left, CEO) and Simon Hinz (Development, IT) present the trophies (© Loginfo24)

Photos: © xpack