Zetes equips Coop Switzerland with 23,500 mobile computers

Sep 22, 2021 at 12:12 PM

Customer Portal myGW from Gebrüder Weiss is a Success

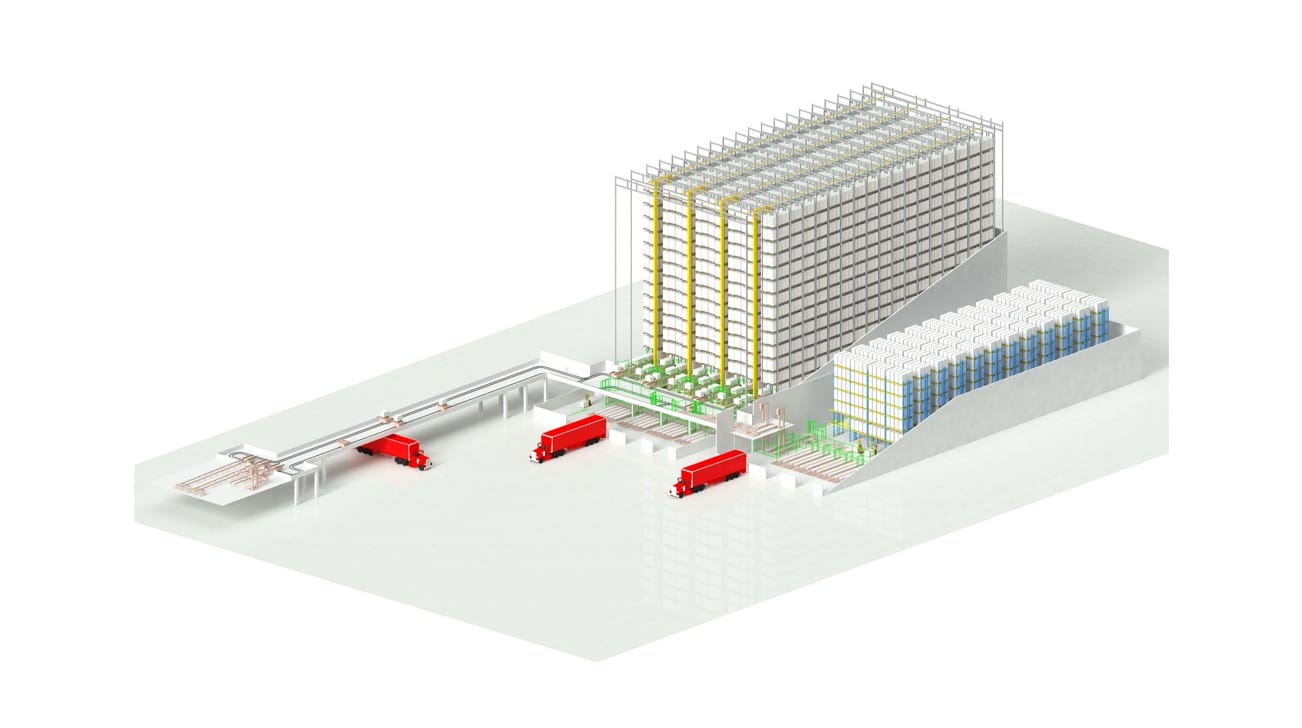

Sep 23, 2021 at 6:36 PMJungheinrich is building an automation solution for Coca-Cola HBC at the Radzymin site in Poland. The new storage system expands the existing facility and offers state-of-the-art technology. Some construction measures will be carried out during ongoing operations. The planned commissioning is in 2022.

(Hamburg/Radzymin) Make full use of available space, create new storage capacities, and achieve higher throughput: This was Coca-Cola HBC’s mandate to Jungheinrich. In implementing this, the Hamburg intralogistics expert relies on the 42-meter high and 60-meter long high-bay warehouse built in silo construction. It ensures maximum space utilization while maintaining high turnover performance. The automatic high-bay warehouse comprises a total of four aisles and provides space for up to 14,000 beverage pallets, which can be stored double-deep. All processes in the high-bay area of the warehouse are fully automated. The experts from Jungheinrich have designed it with the option for expansion: Additional aisles can be easily added at a later date and during ongoing operations.

With Jungheinrich’s new storage solution, the transport route from production is also to be improved. For this purpose, the Hamburg intralogistics expert has modified and expanded the existing conveyor systems: A monorail system with a bridge is now the centerpiece in Radzymin. It transports finished beverage bottles to all available storage locations – both in the new high-bay warehouse and in the automatic warehouse. Jungheinrich’s tailored intralogistics concept allows for optimal material flow between the various areas of the plant.

Setting Standards in Efficiency and Safety

Szymon Matulka, BU Engineering Manager Poland & Baltics at Coca-Cola HBC: “The facility is something special for us. With the automated high-bay warehouse and the improved transport routes, we are setting standards in terms of efficiency and safety. This ensures a consistently high availability of our products.”

Storage and retrieval devices from MIAS, the Jungheinrich subsidiary, also bring speed to the automatic pallet warehouse: Thanks to special devices, high speed is achieved during the storage and retrieval of goods weighing up to seven tons. Additional devices can also be integrated if necessary. Additionally, the existing Warehouse Management System (WMS) has been replaced. In the future, Coca-Cola HBC will use only one WMS for the entire warehouse, which includes various intralogistics solutions. This will manage all systems and processes. The software helps identify potential optimizations, such as the distribution of goods across different storage locations.

New Warehouse Impresses with Optimized Material Flow

Lech Sowinski, Project Manager Technical Sales ASRS at Jungheinrich: “State-of-the-art intralogistics means efficient and economical storage concepts for us at Jungheinrich. This is exactly what the solution we have designed for Coca-Cola HBC in Poland offers. The new warehouse impresses with an optimized material flow. Since all trades come from a single source, rapid integration and optimal communication between the systems are also possible.”

Photo: © Jungheinrich