sennder and JITpay™ Accelerate Payment Processes

Sep 3, 2020 at 6:03 PMSurvey on the Situation of Supply Chains During the Corona Crisis

Sep 4, 2020 at 3:30 PMThe study examines how the transport of temperature-sensitive vaccines can be effectively managed. The current investigation identifies critical issues in COVID-19 logistics. The global delivery of up to 10 billion vaccine doses requires immediate improvements in medical supply chains.

(Bonn) The first emergency approvals for COVID-19 vaccines, expected in the last quarter of 2020, pose a challenge for the logistics industry to organize medical supply chains for the global delivery of an unprecedented amount of more than ten billion individual doses in a very short time frame. Against this backdrop, and in collaboration with analysis partner McKinsey & Company, DHL has published a study addressing the establishment of stable supply chains for vaccines and medical goods during the COVID-19 pandemic and future health crises.

250 Potential Vaccines

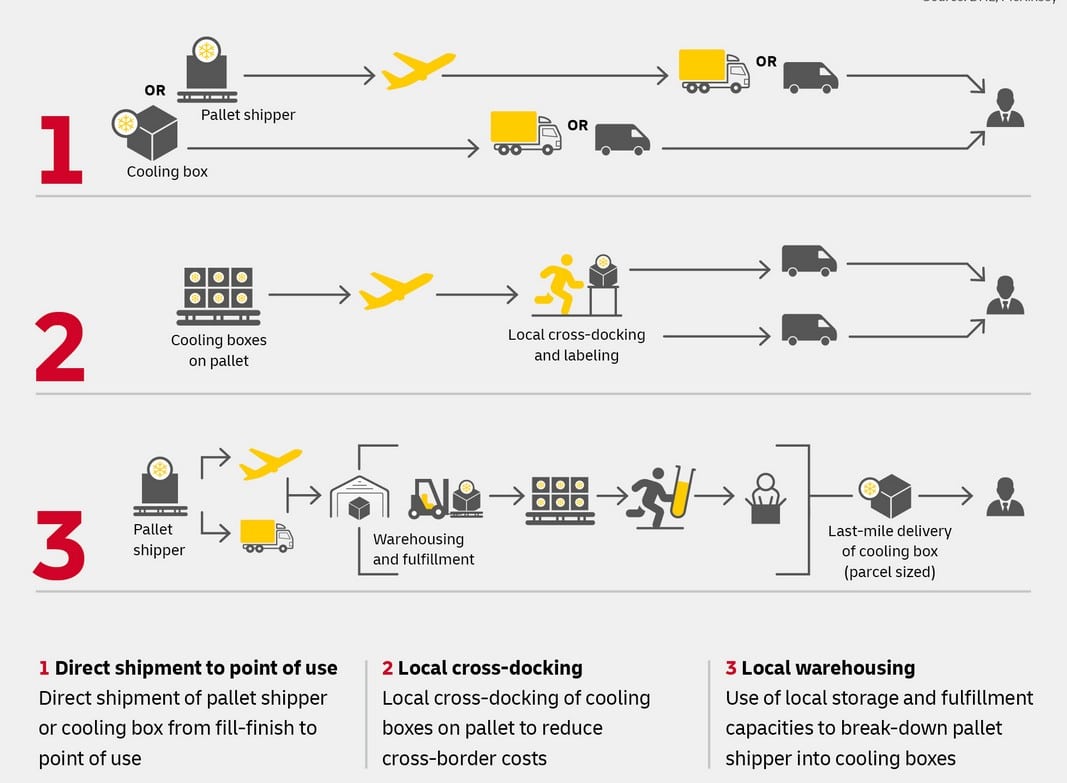

Currently, over 250 potential vaccines are being developed and tested across seven research platforms. Since certain phases of studies for COVID-19 vaccines have been skipped, specific medications may have particularly stringent temperature requirements of up to -80°C to maintain their effectiveness during transport and storage. This presents entirely new logistical challenges for existing medical supply chains, as vaccine distribution typically occurs at temperatures of around 2 to 8°C. The study examines how this transport of highly temperature-sensitive vaccines can be effectively managed to support the fight against the further spread of the virus. To ensure a global supply of COVID-19 vaccines, approximately 200,000 pallet transports, 15 million deliveries in cool boxes, and 15,000 flights will be necessary.

Sharing Experiences

“The COVID-19 crisis has hit us all with an unprecedented magnitude and force. Governments, businesses, and the logistics industry had to quickly adapt to new challenges. As a leading global logistics company, we want to share our experiences and insights from one of the largest health crises in recent history with others to collaboratively develop strategies in an increasingly interconnected world,” explains Katja Busch, Chief Commercial Officer of DHL. “In the current pandemic, governments play a crucial role in shaping medical supply chains to save lives. In recent months, it has been demonstrated that careful planning and suitable partnerships within such supply chains can play a key role when governments move to secure the provision of critical medical goods in crises like these.”

Crisis Management Relies on Public-Private Partnerships

Since the outbreak of the pandemic, the demand for medical supplies has surged significantly. For example, UNICEF procured one hundred times more face masks and two thousand times more medical gloves than in 2019. The supply of medical goods from distant production sources for use in local clinics and practices was one of the central issues in managing the pandemic, especially in the initial phase of the health emergency. Particularly in the area of personal protective equipment, procurement logistics faced significant challenges as production was geographically concentrated, air freight capacities were limited, and there were often insufficient quality controls during imports. To ensure stable medical supply during future health crises, governments must establish a comprehensive system of crisis strategies and structures in public health in collaboration with partners from the public and private sectors.

Framework for Collaboration Between Logistics and Authorities

DHL’s study provides a framework for collaboration between logistics companies and authorities, politicians, NGOs, and the life sciences sector, aiming to initiate dialogue among various stakeholders to improve resilience in medical supply logistics during pandemic times. This framework can help build highly stable and secure supply chains. It includes not only an emergency plan but also a cooperation network, a strong physical logistics infrastructure, and IT-supported supply chain transparency. Last but not least, a crisis team with a clear mandate must be established to implement all critical activities at short notice. Graphics: © DHLwww.dhl.com