RheinCargo Takes Over Shunting and Loading Operations for Shell Tank Farms

Jun 19, 2020 at 7:00 AMDB Schenker Launches Digital Platform for Finding Available Logistics Space

Jun 19, 2020 at 7:02 AMSSI Schäfer has been commissioned by the Swiss Galexis AG to expand the distribution center in Lausanne-Ecublens in western Switzerland. The two companies have a long-standing partnership.

(Neunkirchen) The leading Swiss wholesaler and service provider Galexis AG ensures timely and seamless medication supply for all partners in the healthcare sector. High-quality and modern intralogistics ensure high customer satisfaction and successful market presence. To meet future demands, a comprehensive expansion of the distribution center in Lausanne-Ecublens is being realized, and the location in Niederbipp has already been expanded.

Galexis, a company of the Galenica Group, provides integrated services as a market leader in healthcare logistics across Switzerland. The leading wholesaler and service provider in the Swiss healthcare market ensures timely and comprehensive medication supply throughout the country. At the locations in Niederbipp and Lausanne-Ecublens, Galexis operates powerful distribution centers for the efficient supply of pharmacies, medical practices, drugstores, nursing homes, and hospitals.

Successful Partnership with SSI SCHÄFER

In 2007, SSI SCHÄFER laid the foundation for one of the most modern distribution centers in the Swiss healthcare sector for Galexis at the Niederbipp location. Instead of making costly renovations at the warehouse locations in Bern-Schönbühl and Zürich-Schlieren, Galexis opted for a new, state-of-the-art solution realized with the intralogistics specialist SSI SCHÄFER. In 2016, the warehouse system was expanded with a 3-aisle automated small parts warehouse (AKL) with space for 81,500 containers, as well as a delivery of 65,000 containers to increase the throughput of the overall system to up to 4,000 containers per hour.

Recently, the latest expansion at the Niederbipp location was successfully completed. The existing shipping division for express shipments was enlarged to a total of four shipping areas. With this expansion, the capacity of 4,000 containers/hour can now be processed solely through express shipping. For this purpose, the conveyor line was expanded, and high-speed roller-switches (RSW) were used to optimize throughput. The entire allocation and distribution is automatically and intelligently controlled by the warehouse management software WAMAS®.

New Construction and Capacity Expansion in Lausanne

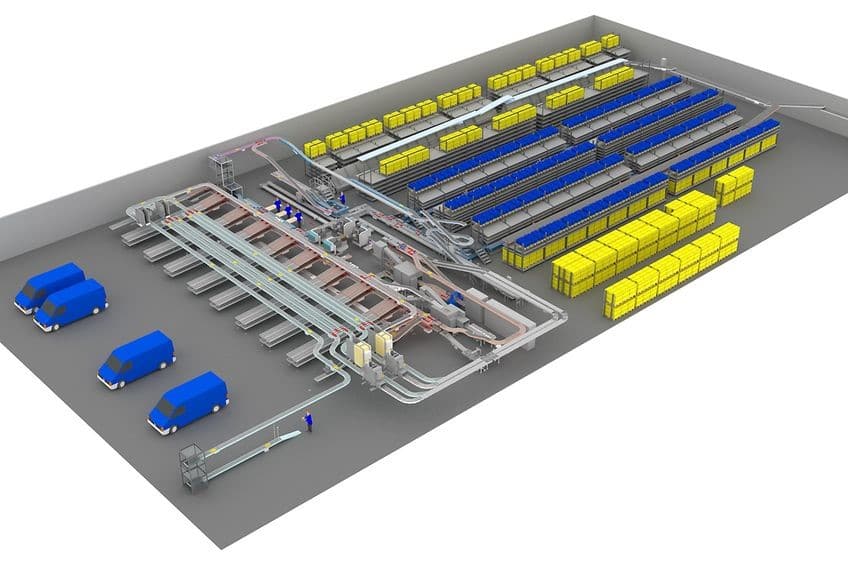

At the Lausanne location, the existing distribution center is currently undergoing extensive expansion and modernization. The project is divided into two phases, which will be completed between mid-2020 and 2022. The distribution center has 4,000 m² of storage space and allows for the processing of 37,000 lines per day.

In the basement, in addition to the existing plant components, eight picking workstations with new flow, pallet, and overstock shelves will be installed. The facility will also be expanded with a second shipping line, including a shipping preparation line with document drop, lidding and inserting, as well as a strapping machine. The increased redundant system design aims to achieve higher reliability and throughput performance.

To increase storage capacity, three zones with four SSI Carousels each will be implemented on the ground floor. The technology already used in the distribution center in Niederbipp from SSI SCHÄFER expands the capacity by 18,000 containers, thus sustainably supporting the supply of western Switzerland. The SSI Carousels are supplied by ten goods-in stations and are connected by several hundred meters of container conveyor technology. The basement will also be served by these goods-in stations, with old cartons being removed from the workstations via an integrated old carton conveyor. Order picking is carried out via three ergonomic Get and Pick Stations, which can achieve a picking performance of up to 2,250 lines/hour.

Pallet and cantilever racks round off the modern concept and serve as overstock buffers as well as a pallet picking area for large containers. A new roll cart conveyor technology with a lift will automatically convey cross-docking deliveries to the shipping area in the future. For items with increased storage temperature requirements, a cooling area with shelves and a picking station will also be installed. A new version of the warehouse management software WAMAS will be used for the overall project, which will be connected to the SAP EWM of Galexis.

With the planned expansions, Galexis AG is responding to market needs and reaffirms its long-standing and successful partnership with the intralogistics specialist SSI SCHÄFER.

Photo and graphics: © SSI Schäfer